Introduction

In the realm of electrical engineering, the health and efficiency of transformer components stand paramount. These components, integral to the very fabric of power distribution and electrical asset management, have long warranted keen monitoring. As the industry evolved, so did the methods to keep a watchful eye on these vital components. This article embarks on a journey through the annals of traditional monitoring techniques, ventures into the revolution brought about by comprehensive solutions, and projects a gaze into what the future holds. For professionals involved in every facet of this industry, understanding these advancements is not just a matter of knowledge but a requisite for optimal asset management.

Historical Perspective: Traditional Monitoring Techniques

Traditionally, transformer components were monitored through manual inspections, periodic checks, and standalone instruments. These methods, though reliable for their time, had limitations in terms of real-time data, predictive analysis, and comprehensive coverage. Delving deeper into these traditional techniques reveals both their strengths and inherent challenges.

The genesis of transformer monitoring is rooted in the foundational principles of electrical engineering. With transformers being pivotal for power distribution, ensuring their optimal operation and health has always been a cornerstone of electrical asset management. Embark on a journey through history to explore the methods that were once considered the pinnacle for monitoring transformer components.

Manual Inspections and Periodic Checks

In the early days, transformer health was primarily ascertained through manual inspections. Engineers and technicians would physically examine transformer components, looking for visible signs of wear, tear, or damage. These inspections were often supplemented with periodic checks using basic instruments to measure parameters like voltage, current, and temperature. While reliable, these methods were time-consuming and lacked real-time responsiveness.

Standalone Instruments and Monitoring Devices

With technological advancement, the industry saw the introduction of standalone monitoring devices specifically designed for transformer components. These devices, though rudimentary by today’s standards, offered more precise measurements and data logging capabilities. However, they are still operated in isolation, requiring manual data retrieval and interpretation.

Challenges and Limitations

Traditional techniques, despite their reliability, came with inherent challenges. The lack of real-time data meant that potential issues could go unnoticed until the next scheduled inspection. Moreover, predicting failures was nearly impossible, making maintenance more reactive than proactive. The absence of comprehensive monitoring solutions meant that a holistic view of transformer health was often fragmented and siloed.

Transition to Modern Monitoring

As the electrical industry grew, so did the demand for more sophisticated monitoring solutions. The limitations of traditional techniques were becoming increasingly evident, paving the way for the advent of comprehensive monitoring solutions. These solutions, which harnessed the power of software and advanced electronics, promised not just real-time monitoring but predictive analytics, setting the stage for the next chapter in transformer component monitoring.

The Revolution of Comprehensive Monitoring Solutions

The dawn of the digital age ushered in a new era for transformer component monitoring. Comprehensive solutions, driven by advanced software, now offer holistic monitoring, covering all components simultaneously. These modern systems are not just about detecting issues but predicting them, offering an unparalleled advantage in proactive maintenance.

The electrical asset monitoring realm has witnessed a sea change in the last few decades. From rudimentary manual checks to state-of-the-art comprehensive monitoring solutions, the journey has been transformative. This evolution was fueled not just by technological advancements but also by the increasing demand for real-time, predictive insights. In this section, we delve into the modern-day solutions that have revolutionized the way we monitor transformer components.

Birth of Integrated Systems

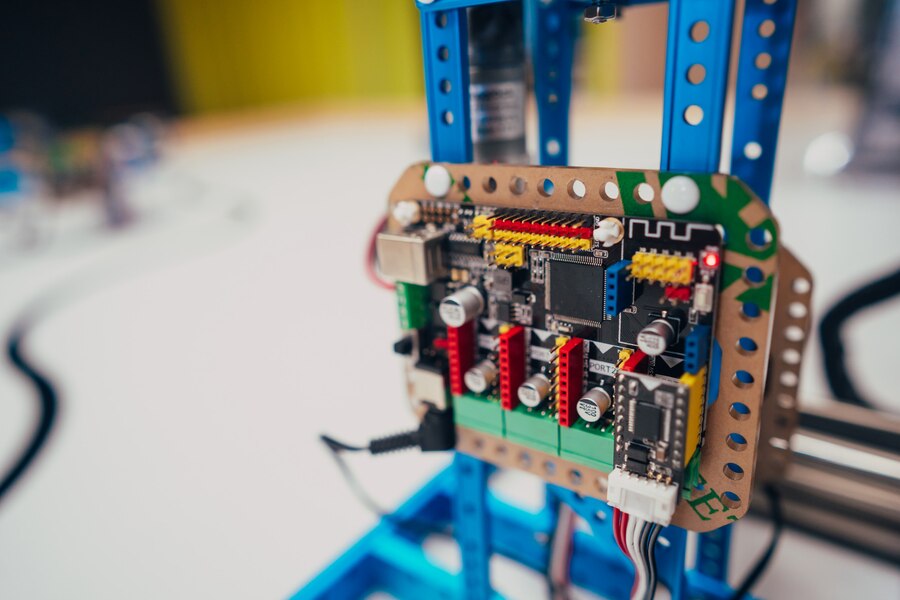

The dawn of the 21st century brought with it integrated monitoring systems. Unlike their predecessors, these systems were designed to be interconnected, allowing for continuous data collection and instantaneous analysis. They harnessed the power of advanced sensors, telemetry, and software algorithms, ensuring that every aspect of transformer components, from temperature to voltage fluctuations, was under scrutiny.

Predictive Analytics and Proactive Maintenance

One of the game-changers in the comprehensive monitoring solutions is predictive analytics. By analysing data trends and patterns, these solutions can forecast potential failures or malfunctions. This not only reduces downtimes but also aids in proactive maintenance, ensuring transformer longevity and reliability.

Remote Monitoring and Cloud Integration

The advent of IoT (Internet of Things) and cloud computing further bolstered the capabilities of monitoring solutions. Today, engineers and asset managers can monitor transformer components remotely, accessing real-time data from anywhere in the world. Cloud integration also ensures secure data storage, easy access, and seamless collaboration among teams.

Enhanced Safety and Efficiency

Harnessing comprehensive monitoring solutions has had a profound impact on transformer safety. Real-time alerts and alarms can pre-empt catastrophic failures, safeguarding both assets and personnel. Additionally, these solutions have optimized energy efficiency, ensuring that transformers operate at their peak performance levels, translating to cost savings in the long run.

Key Features and Advantages of Modern Monitoring Solutions

Modern monitoring systems are characterized by their real-time data collection, predictive analytics, remote monitoring capabilities, and integration with other systems. These features collectively enhance efficiency, reduce downtimes, and ensure the longevity of transformer components. A detailed exploration of these features provides insights into their tangible benefits and the edge they offer to electrical asset managers.

As technology evolves, so does the sophistication of electrical asset monitoring solutions. Modern-day monitoring tools boast a plethora of features, each designed to enhance the accuracy, efficiency, and safety of monitoring transformer components. Let’s explore some of the standout features of these systems and understand the advantages they bring to the table.

Real-Time Data Acquisition

Today’s monitoring solutions are equipped with advanced sensors that continuously collect data from transformer components. This real-time data acquisition ensures that engineers and asset managers have the most up-to-date information on transformer health, enabling swift decision-making and immediate response to anomalies.

Predictive Maintenance Capabilities

Harnessing the power of AI and machine learning, modern solutions can analyze trends and predict potential issues. This predictive maintenance capability means that problems can be addressed before they escalate, significantly reducing downtime and maintenance costs.

Remote Access and Control

With cloud integration and IoT, users can remotely monitor and control transformer operations from anywhere globally. This remote access feature ensures that even in remote installations, transformer components are never out of sight, enhancing operational flexibility.

Enhanced Security Protocols

Modern monitoring solutions prioritize data security. With encrypted data transmission, multi-layered authentication processes, and regular software updates, these tools offer robust protection against cyber threats, ensuring that sensitive transformer data remains uncompromised.

Real-World Application: Case Studies of Successful Implementations

The true testament to the prowess of modern monitoring solutions lies in their real-world applications. Numerous organizations have transitioned to these advanced systems, reaping benefits in terms of cost savings, reduced downtimes, and enhanced asset life. Delving into these case studies offers a practical perspective on the transformative power of comprehensive monitoring.

Modern monitoring solutions have revolutionized the way we perceive and handle transformer components’ health. However, the proof of their efficacy lies in their real-world applications. In this section, we will delve into a couple of case studies that highlight the successful implementation of these advanced monitoring solutions and the tangible benefits reaped by companies.

Case Study 1: Utility Company Boosts Operational Efficiency

A leading utility company, after implementing comprehensive monitoring solutions, reported a 20% reduction in unplanned downtimes. By harnessing real-time data from transformer components, they could pre-emptively address wear and tear, ensuring uninterrupted power supply to their consumers. Moreover, the solutions’ predictive maintenance feature helped the company save significant costs that would otherwise be spent on emergency repairs.

Case Study 2: Industrial Plant Enhances Safety Protocols

An industrial plant, dealing with high-voltage machinery, incorporated advanced monitoring tools to oversee its transformer components. The remote monitoring capabilities allowed the safety inspectors to detect and rectify potential hazards without exposing themselves to the dangers of the plant floor. As a result, there was a 15% decline in safety incidents within a year.

Harnessing Data for Informed Decisions

Multiple industries, from energy sectors to manufacturing units, have tapped into the power of modern monitoring solutions. These tools not only provide insights into the health of transformer components but also empower decision-makers with data-driven insights, leading to more informed, strategic choices.

Conclusion of Case Studies

The aforementioned case studies underscore the transformative potential of comprehensive monitoring solutions in real-world scenarios. When applied strategically, these tools can drive efficiency, enhance safety, and ultimately, contribute to an organization’s bottom line.

Looking Ahead: The Next Phases in Transformer Component Monitoring

As technology continues to evolve, so will the methods to monitor transformer components. The horizon promises even more integrated solutions, AI-driven analytics, and perhaps, autonomous maintenance systems. A speculative yet informed look into the future paints a picture of endless possibilities and advancements.

As technology continues to evolve at a rapid pace, the electrical asset monitoring industry is positioned at the forefront of innovation. The monitoring of transformer components, in particular, is undergoing a period of significant transformation, fueled by advancements in software capabilities and the increasing demands of modern electrical systems.

Integration of Artificial Intelligence

The incorporation of Artificial Intelligence (AI) into monitoring solutions is set to redefine the dynamics of transformer component surveillance. AI-driven predictive analytics can process vast amounts of data in real-time, identifying patterns and anomalies that might escape manual monitoring. This will drastically enhance the accuracy and speed of fault detection, thereby prolonging the lifespan of transformer components.

Increased Emphasis on Cybersecurity

As monitoring systems become more interconnected and reliant on digital platforms, the need for robust cybersecurity measures grows paramount. Future monitoring solutions will prioritize end-to-end encryption, multi-factor authentication, and regular security audits to protect sensitive data and ensure uninterrupted monitoring operations.

Harnessing the Power of the Internet of Things (IoT)

The IoT revolution offers immense potential for transformer component monitoring. By connecting sensors, devices, and systems, there’s an opportunity for a more holistic monitoring approach. This interconnected ecosystem will facilitate real-time data sharing, enabling faster decision-making and more coordinated maintenance efforts.

Sustainability and Green Monitoring Solutions

The global push towards sustainability is influencing the development of eco-friendly monitoring solutions. These tools will prioritize energy efficiency, minimize wastage, and incorporate sustainable materials, aligning with global environmental objectives.

Conclusion on Future Trends

The future of transformer component monitoring is undeniably promising. With technological advancements like AI, IoT, and an emphasis on cybersecurity and sustainability, monitoring solutions will become more efficient, secure, and environmentally responsible. For industries and professionals in the electrical domain, keeping abreast of these trends will be crucial to harness the full potential of modern monitoring solutions.

Conclusion

The journey from manual checks to sophisticated, software-driven monitoring systems encapsulates the relentless pursuit of efficiency and excellence in the field of electrical engineering. As transformer and its components remain central to power distribution, ensuring their health and longevity becomes imperative. Comprehensive monitoring solutions, with their myriad advantages, stand as the beacon of this pursuit. For professionals navigating this domain, embracing these advancements is not just about staying updated; it’s about envisioning and shaping the future of electrical asset management.