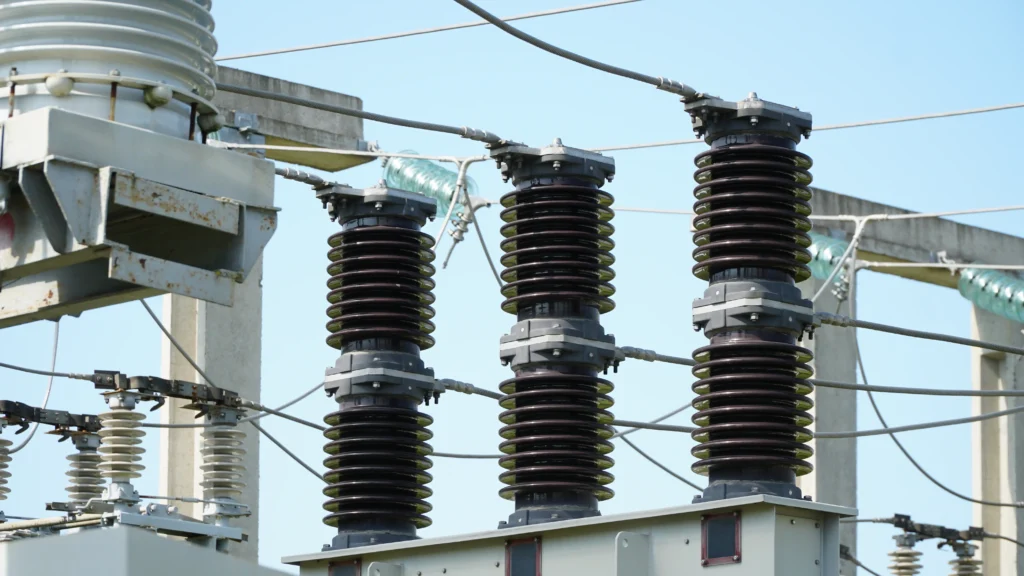

In this blog, we’ll examine the five fundamental bushing diagnostic techniques essential for evaluating the bushings’ insulation health.

In the first part of this bushing monitoring series, we covered how gradual failures allow for preventive planning while rapid-onset failures demand immediate response capabilities, emphasizing the importance of tailored bushing monitoring solutions. In this second part, we will discuss each method, offering insights into specific facets of insulation integrity, and together, they provide a comprehensive view of bushing conditions.

Coordinated Bushing Diagnostic Techniques for Condition Monitoring

Accurately assessing the condition of a bushing insulation system is critical to ensuring transformer reliability, safety, and longevity. Each bushing diagnostic technique offers insights into specific aspects of the insulation’s health. Rather than relying on a single data point, an integrated approach across various dimensions- electrical, thermal, and dielectric- helps create a comprehensive view of bushing integrity.

This combined approach also helps us distinguish between transient anomalies and genuine deterioration, reducing the risk of false alarms while ensuring that early signs of failure are not missed. Thus, the result is a more condition-based bushing monitoring that empowers asset managers to act with foresight, maintain performance standards, and ensure grid stability with minimal disruption.

The following are the five most fundamental methods to enhance the depth and accuracy of bushing monitoring.

1. Dielectric Dissipation Factor (Tan δ) Measurement

The dielectric dissipation factor, or Tan δ, is the primary and most reliable method for evaluating bushing insulation health. This measurement assesses the ratio of resistive to capacitive currents in the insulation, revealing the amount of energy lost as heat. It is particularly effective in identifying moisture ingress, contamination, or insulation aging.

-

How It Works:

Tan δ measures the phase shift between the applied voltage and the resulting current in the insulation. Higher Tan δ values indicate increased resistive losses, suggesting moisture ingress or contamination. In healthy bushing, the dielectric loss is minimal; however, the dissipation factor rises as insulation degrades due to moisture or thermal aging.

-

Sensitivity to Moisture and Contamination:

This method is susceptible to moisture content in the insulation material. For example, even minor moisture ingress can significantly increase Tan δ values, highlighting its value in early-stage diagnostics. The Tan δ test is especially relevant for outdoor bushings, which are more susceptible to environmental contamination.

-

Trend Analysis:

Regularly tracking Tan δ values over time helps create a historical baseline for each bushing. By establishing normal fluctuations, utilities can detect early deviations that may indicate emerging issues, allowing for predictive maintenance before any significant degradation occurs.

2. Capacitance Measurement

Capacitance measurement is another core bushing diagnostic technique for assessing bushing health. It is particularly useful in identifying partial breakdowns or contact issues within the condenser core. Since bushings are typically designed with a series of capacitive layers to manage high voltage gradients, any degradation in these layers affects the overall capacitance.

-

How It Works:

In a healthy bushing, the capacitance remains stable. However, insulation defects such as moisture ingress, aging, and partial discharges cause fluctuations in capacitance values. This is because the breakdown of capacitive layers disrupts the electrical field within the bushing.

-

Identifying Partial Breakdown:

Capacitance measurements are highly effective at detecting partial breakdowns or short circuits between capacitive layers. These issues may start small but can escalate quickly, leading to localized heating and potential internal discharges. Since each layer in the condenser core is carefully calibrated, even minor deviations in capacitance can signal significant internal issues.

-

Challenges in Detection:

High-voltage transformers, especially those above 420 kV, may have capacitive layer counts ranging from 60 to 100. Even with a breakdown in one or two layers, capacitance variation may be minimal, requiring highly sensitive equipment and regular trend analysis to capture early signs of failure.

3. Dissolved Gas Analysis (DGA)

Dissolved Gas Analysis (DGA) is particularly valuable for oil-impregnated paper (OIP) bushings. DGA provides insights into the insulation system’s chemical stability by detecting gases dissolved in the insulation oil. Different gases indicate specific types of degradation, making DGA a powerful tool for identifying insulation faults.

-

How It Works:

DGA identifies gases such as hydrogen, methane, ethylene, and acetylene within the oil. Each gas correlates with specific fault types—hydrogen and methane are typically associated with partial discharge, while ethylene and acetylene indicate arcing or high-temperature overheating. DGA can diagnose fault types and even estimate their severity by analyzing gas concentrations and ratios.

-

Sensitivity to Thermal and Electrical Faults:

DGA is particularly effective at detecting arcing, partial discharge, and overheating, which are standard failure modes in OIP bushings. Even low-level PD activity produces detectable gas levels over time, allowing operators to intervene before faults progress.

-

Trend and Ratio Analysis:

Similar to Tan δ, DGA requires a baseline of historical gas levels. Ratio analysis, such as the Duval Triangle or Rogers Ratio, is used to interpret gas concentrations and diagnose specific fault types. For instance, high levels of acetylene and ethylene typically indicate electrical arcing, while hydrogen and methane suggest overheating.

4. Partial Discharge (PD) Measurement

Partial discharge measurement is increasingly employed in bushing diagnostics to detect small-scale discharges that indicate insulation weakness or structural defects. PD can occur due to voids within the insulation or electrical stresses, which may eventually escalate to a complete breakdown.

-

How It Works:

PD sensors capture electromagnetic emissions generated by discharges within the insulation. PD activity generally indicates insulation deterioration, particularly at defect sites where electrical stress concentrates. As PD increases, it generates localized heating and further weakens the insulation, leading to progressive degradation.

-

Detection Sensitivity:

PD measurement is sensitive to early-stage failures that may not yet affect Tan δ or capacitance values. For example, voids or contaminants in the insulation may not immediately change capacitance but can produce detectable PD activity.

-

Advanced PD Monitoring:

Real-time PD monitoring is especially beneficial for high-voltage transformers, as it continuously captures discharge activity, providing operators with immediate alerts. Combined with other measurements, such as Tan δ and capacitance, PD data contributes to a comprehensive diagnostic picture.

5. Infrared Thermography

Infrared (IR) thermography is a non-contact bushing diagnostic technique that detects hot spots in bushings, often due to resistive losses, loose connections, or insulation degradation. This technique is particularly effective for spotting external abnormalities in bushings.

-

How It Works:

An IR camera measures the heat emitted from the bushing surface, identifying abnormal temperature patterns. Hot spots usually indicate resistive heating, which can arise from internal faults or poor connections. By capturing heat anomalies, IR thermography provides an indirect yet useful indication of internal bushing health.

-

Integration with Other Bushing Methods:

While IR thermography alone does not diagnose all insulation issues, it’s highly effective alongside other tests. For example, an elevated Tan δ value combined with a hot spot detected by IR thermography strongly indicates insulation deterioration, warranting further investigation.

Integrating Bushing Diagnostic Techniques for Comprehensive Health Assessment

Each bushing diagnostic technique has unique strengths and limitations. When used individually, they provide valuable but limited insights and form a comprehensive diagnostic framework when combined. For example:

-

Tan δ and Capacitance:

Using these measurements together helps differentiate between aging and contamination versus structural breakdown within the insulation. A gradual rise in Tan δ with stable capacitance suggests moisture or contamination, while changes in both could indicate severe aging or breakdowns.

-

DGA and PD:

In oil-impregnated bushings, DGA and PD measurements offer complementary insights into thermal and electrical faults. High PD activity with elevated DGA gas levels, particularly acetylene, indicates arcing or severe discharge activity.

-

Trend Analysis and Real-Time Bushing Monitoring:

Regularly scheduled measurements combined with real-time monitoring allow operators to establish baselines, detect anomalies early, and predict failures before they occur. This approach is efficient for high-value assets, where unplanned downtime can be costly.

The combination of bushing diagnostic methods, such as Tan δ measurement, capacitance, DGA, PD monitoring, and infrared thermography, enables utilities to assess bushing insulation health effectively. However, effective bushing diagnostics are only half the solution. As assets age and industry demands evolve, predictive and condition-based monitoring become essential tools for proactive maintenance.

In Part 3, we’ll see how predictive analytics, real-time monitoring, and Rugged Monitoring’s technology stack work together to deliver actionable insights and prevent failures before they occur. Stay tuned to discover how modern monitoring transforms reactive maintenance into a strategic advantage.